With the development of wind power, dispersed low speed wind generation system development is the key point of future wind power development. In 2011, China has built a trial wind farm in Anhui province, which is mainly focused on low wind speed power generation. Right now, China wind power market has fully stepped into the low wind speed power generation, as Chinese low speed wind power generation receives a large-scale development in both mid-east region and southern China.

With the development of wind energy technology, the wind source with a speed under 6m/s can also be used into commercial wind energy generation. The key point of low speed wind power technology is to improve the utilization of wind energy of wind turbine tower systems in low wind speed environment, then the power generation cost can be reduced. As an main part of wind power generation system, to improve the power generation efficiency, wind turbine tower must also be improved to meet the requirements of low wind speed power generation.

High Wind Turbine Tower Improve Power Generation

In November, 2016, the 120 meters high steel wind turbine towers with low speed smart wind turbines has been installed in Jiangsu province, and all these wind turbine tower systems have been successfully operated and connected in the national grid. Moreover, in December, the big wind turbine manufacturer, VESTAS, announced that their next wind farm in construction in Shandong province will use the high wind turbine tower technology, and the highest steel wind tower about 137 meters high.

Recently, as the wind turbine unit capacity keeps growing, the length of wind turbine rotors grows, too. In that way, the height of wind turbine towers have to be higher and higher. It has becoming an irreversible trend of wind energy industry. For low speed wind energy development, to enhance the length of wind turbine rotors and the height of wind turbine towers will make the utilization of wind energy source more sufficiently. These are the main methods to improve electric energy production.

The energy captured from wind is deeply related to the rotor swept area and the wind power density. Enhance the length of wind turbine rotors increases the swept areas of wind turbine rotors. Therefore, it can capture more wind energy and elevate the electric energy production. But there is a limit of increasing the diameter of wind turbine rotors, the oversized wind turbine rotor diameter will increase wind turbine load, which will surely increase wind energy generation cost.

In such a long period, we prefer to use the method of increasing wind turbine rotor length to raise electric generation quantity in Chinese wind power market. This is mainly because the traditional steel wind tower manufacturing technology limits. When the height of wind turbine tower increases, we must face the technical difficulties of maintaining the thickness of wind turbine tower wall, the height and weight limits during wind tower transportation and the controlling of wind tower manufacturing cost. But recent years, as the high wind tower technology matures, now we can increase the power generation quantity by adding the height of wind turbine towers.

Right now, Chinese low wind speed development has reached a new low limit of 5m/s, how to make the low speed wind farm project profitable is the key problem of wind power technology revolution. For example, if the shearing factor of wind is 0.3, compare to 90m wind towers, 120m wind tower technology can create over 300 extra hours power generating benefits. Which means more low wind speed areas have the possibility and higher economy of developing low speed wind power.

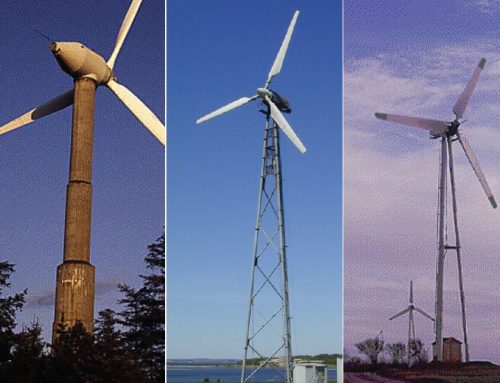

Chinese high wind turbine tower technology can be divided into two types, complete steel wind tower and concrete steel hybrid wind tower. Complete steel wind towers are famous for the low cost, traditional structure, mature supply chain, convenient transportation, efficient lifting installation method. The good performance of steel wind turbine tower benefits from the intelligent control technique of smart wind turbines. The design of concrete steel hybrid wind tower is simple, and there is no extra requirements of the wind tower control strategies. But concrete steel hybrid wind tower requires complicated construction technology and the expensive preformed parts makes the construction period of hybrid wind tower longer. And the reliability of the construction team and the rich and successful construction experiences are the short board of concrete steel hybrid wind turbine tower market.

There is no end to technological innovation. Most of the people believes that under the background of low wind speed areas becomes the key point of wind power development, high steel wind turbine tower technology will keep growing as the economic growth of low speed wind turbine systems and the construction experience grows.