Wind energy is a type of solar energy. Because of the unevenly sunlight distribution, the uneven atmosphere pressure distribution has been created. Therefore, the air moves under the action of atmosphere pressure, and wind has been generated.

With modern wind turbine technology, wind can be turned into electricity, which is one of the cleanest ways for energy generation. As the environment pollution problem becomes the main focus of the entire world, the whole world is eager to find out the clean ways to generate energy in order to replace fossil fuels. Nowadays, you can see wind farms around the world, especially the coastal areas.

As we all know, the air flow rate increases when the altitude increases, and higher air flow rate creates larger kinetic power. Therefore, the industrial wind farms always adopts steel wind turbine towers with dozens of meters high.

Something About Wind Turbine

A wind farm is consists of several wind power generation systems, and a wind power generation system is consists of a wind turbine and a wind turbine tower to support the wind turbine in a certain height.

Wind turbine is a device that can turn the kinetic energy of wind into electricity, and with the underground grid, the electricity can be transport to the end users. Wind turbines look like propellers, strong wind can make the blades spinning round and through a electric generator, the kinetic energy has been convert to electric current.

Wind Turbine Details

Normally, there are two types of wind turbines, the horizontal axis wind turbines and vertical axis wind turbines. Horizontal axis wind turbine is the traditional wind turbine that has been used in the industrial wind farm around the world. One of the famous model of vertical axis wind turbine is the eggbeater style Darrieus wind turbine, which is named after its inventor. But vertical axis wind turbine is mostly used for small wind energy generation systems. For industrial wind farms, horizontal axis wind turbine is the dominant wind turbine type.

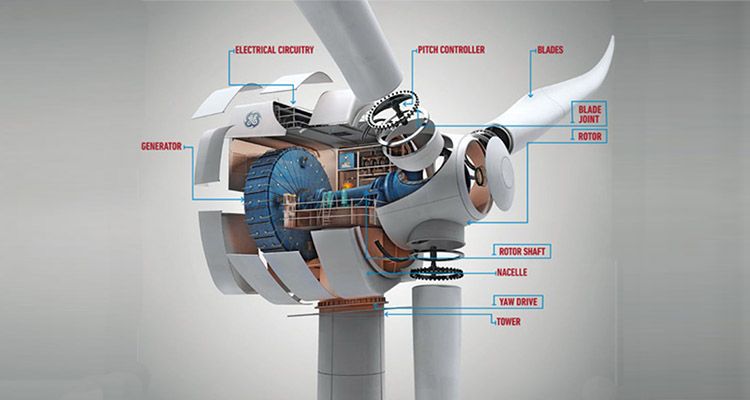

A standard horizontal wind turbine normally consists of several components: the nacelle, the blades, hub, gearbox, low speed shaft, high speed shaft with the mechanical brake, electrical generator, yaw mechanism, electronic controller, hydraulics system, cooling unit, anemometer and the wind vane.

Something About Wind Turbine Tower

Wind turbine tower is the pole that support the wind turbines. Higher wind speed create larger kinetic energy, and the higher altitude areas always have higher wind speed. Therefore, to reach the industrial electricity generation requirements, wind turbines must stays at a certain height, which a wind turbine tower is needed.

For industrial wind farms, the height of wind turbine towers usually about dozens of meters high, in some areas, there are wind turbine towers over a hundred meters. With such a height, the stiffness of wind turbine towers is a main focus for all the wind farm investors.

Even through the wind turbine technology has been improved, it still vibrate during working. So the wind turbine towers need to be stiff enough to sustain the attack of extreme whether such as typhoon and storm, and the vibration of wind turbine.

To maximum the rigidity of wind turbine towers, we have developed the concrete wind turbine towers, but after years use experience, many people find out that concrete wind turbine tower needs long construction period, and when the concrete wind turbine tower stops using, the wastes after rejection are not disposed, which will create environment pollution problems. Therefore, recent days, steel wind turbine towers have dominant the industrial wind energy generation industry. You can find beautiful steel wind turbine towers all over the world. And because of its significant height, the adventurers also starts a wind turbine tower climbing activity, which creates an ancillary income for the wind farms.

Wind Turbine Tower Details

For industrial wind energy industry, steel wind turbine tower dominates the market. A steel wind turbine tower is consist of several tower sections, and the diameter of upper wind tower section are smaller than the lower wind tower section. On each ends of the wind turbine tower section are welded with wind tower flanges, therefore, with the bolts, the neighboring wind tower sections can be connected tightly. Wind turbine towers normally have to face a corrosive environment, for offshore wind farms, the wind turbine towers will be soaked in water, and for onshore wind farms, the wind turbine towers always be built at open areas, therefore the wind towers have to suffer strong wind, strong sunlight and so on. In order to enhance the serve life of wind turbine tower, the tower sections will go through several surface treatment before it can be transport to the wind farm. A complete wind tower coating treatment includes several different parts, sand blasting, and multilayer anti corrosive coating. After the surface treatment, wind turbine towers maintains better performance of UV-resistance, non-discoloring, and weathering resistance.