The first offshore wind farm was successfully built and went into service in Denmark in 1991. The wind farm is consist of 11 wind power generating systems with an installed capacity of 450kw each. When stepping into the 21 century, every one has to face the severe energy and ecological conjuncture, which brings renewable energy such as solar, wind, water, biomass into our life. Right now, many European countries have already built some large scale offshore wind farms in order to adjust their energy structure of electric power.

Offshore Wind Farm Components

A complete wind farm is consist of a certain numbers of wind power generating systems and the power transmission system.

Wind Power Generating System

A single wind power generating system includes the blades, wind turbine, wind turbine tower (tower sections and tower internals) and the foundation part.

Wind Turbine & Blades

The principle of aerodynamics can be used in many ways, which the design and development of wind turbine is one of them. For common people, it seems like the wind pushes the wind turbine blades to rotate, which creates electric powers. Actually, the rotation of wind turbine blades is caused by the pressure difference between the blade front side pressure and back side pressure which is formed when the wind blows. The pressure difference will create lift force, which makes the wind turbine rotate and drives the rotation of electric generator rotors through wind turbine gearbox. Therefore, wind turbine and blades can turn wind kinetic energy (air kinetic energy) into the kinetic energy of wind turbine electric generator rotors, and then the kinetic energy of rotors of wind turbine electric generators will be turned into electric energy.

Wind Turbine Towers

The wind turbine towers for wind power generating systems are made of quality steel plate. The design of wind turbine towers must considers many different aspects, such as the rigidity and stability of wind turbine tower in the extreme environments, like storm, typhoon, etc. In order to make the wind turbine blades is positioned at the height with richest wind resources, the height of offshore wind turbine towers is determined by the wind situation and water situation onsite, and the diameter of wind turbine blades.

Inside wind towers, there are also many types of wind tower internals. In order to transport the electric back to underground grid, cables are placed inside wind turbine towers. For further operation, there are lights, platform, ladders, etc.

Wind Tower Foundation Parts

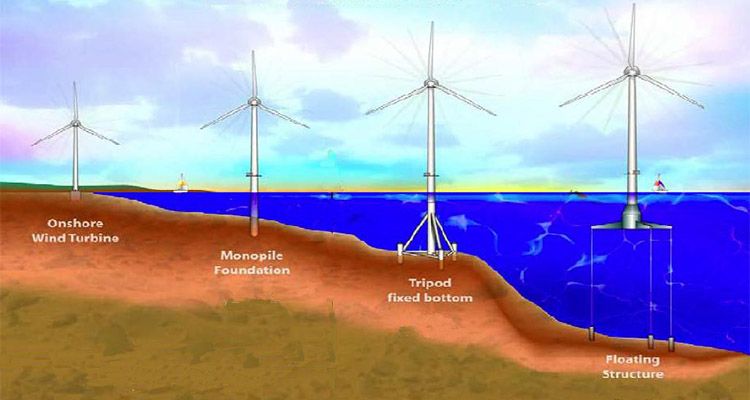

For offshore wind energy generating systems, wind turbine tower foundation is used to fix the complete wind energy generating systems. There are four types of offshore wind turbine tower foundations: gravity wind tower foundation, Monopile wind tower foundation, tripod fixed bottom wind tower foundation, floating structure wind tower foundation.

Different types of offshore wind turbine tower foundation application ranges:

- Gravity Foundation: this type of wind tower foundation used for land based offshore wind farms. It uses huge amount of concrete to fix the wind tower.

- Monopile Foundation: this type of wind tower foundation used for offshore wind farms located at the water areas shallower than 30 meters. Used the methods like piling, drilling, jetting to install the monopile base in the sea floor.

- Tripod Foundation: this type of wind tower foundation used for offshore wind farms located at the water areas between 30 meters and 60 meters. It is much more stable than monopile wind tower foundations, but the cost of tripod wind tower foundation is also higher.

- Float Foundation: this type of wind tower foundation used for offshore wind farms located at the deep water areas deeper than 60 meters. As the stability of float wind tower foundation is lower than monopile foundation and tripod foundation, so it can only be used in the water areas with small waves.

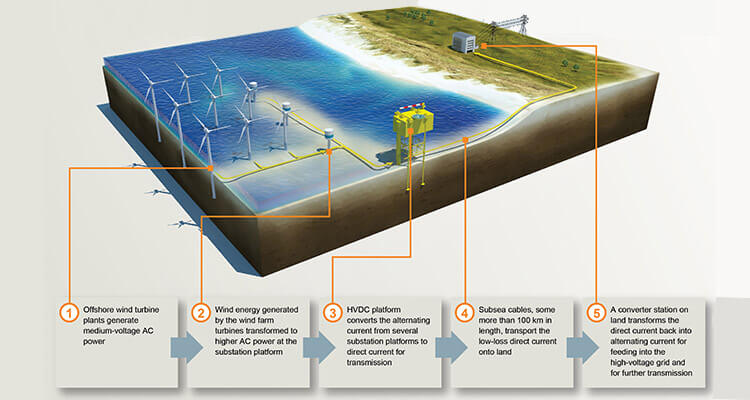

Power Transmission System

So far, the majority of offshore wind farms adopts HVAC power transmission systems, which is consist of the following parts: ac power circuit, offshore booster station and reactive power compensation equipment, submarine cable, onshore power substation and reactive power compensation equipment. Through the ac power circuit, the electric power generated by each wind power generating system has been collected together. Then, use the offshore booster station to rise the electric voltage and transmit the electric power to the onshore power substation.

How to Build A Offshore Wind Farm

The construction of offshore wind farm can also be called as the construction of offshore wind power generating system. An offshore wind farm is consist of several offshore wind power generating systems. So offshore wind farm construction process is the repeat of offshore wind power generating system construction process.

Offshore Wind Power Generating System Construction Platform

The construction of offshore wind power systems can be managed through jack up barges or floating cranes.

Installation Methods of Offshore Wind Power Generating System

According to the Opti-OWECS report released by Europe offshore wind farm construction projects, there are three installation methods to install offshore wind power generating systems: jack-up installation, semi-submersible installation and float-over installation. The choice of these three installation methods mainly depends on the depth of the water area, the capacity of the lifting machine and the load capacity of barges.

Offshore Wind Power Generating System Installation Process

The installation process of offshore wind power systems can be divided into two parts: the construction of wind tower foundation and the installation of wind tower and wind turbine. Typically, the tower internals and cables will installed first onshore, and then, transport the whole set to the offshore wind farm, and install the wind power system parts in the following order: wind tower foundation part, each tower sections, wind turbine, and wind turbine blades.