Wind turbine tower is a typical high-rise structure building.

The average wind tower height on earth is around 90m – 130m.

The wind turbine foundation bears the load transmitted from the wind turbine tower and the turbine on the top, especially the huge overturning moments.

For onshore wind turbine tower, there are basically 5 common types of wind tower foundations: the shallow mat extension, the ribbed beam basement, the underneath piled foundation, the uplift anchors and the new type.

For each type, it can be both in round shape or in octagon shape. The diameter ranges from 15m to 22m.

1.The shallow mat extension

shallow mat type wind turbine tower foundation

shallow mat type wind turbine tower foundation with cover

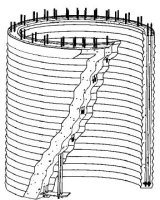

The round shaped shallow mat type wind turbine tower foundation includes three parts: the basement, the mat, and the central pillar.

The pros: this module is easy to build, the construction period is short, it can be used widely for a large range of wind turbine tower capacity. Suitable for the plain area and hilly land.

The cons: larger basement area needed, more excavation and digging work, more concrete and steel material required, not environmental friendly.

2. The ribbed beam basement

ribbed beam wind turbine tower foundation

The ribbed beam type wind turbine tower foundation also includes 3 parts: the basement, the beams and the central pillar. Unlike the shallow mat type, the beams are designed to counter the overturning moments.

The pros: the basement is slim, less concrete or steel needed. Suitable for the plain area.

The cons: Larger basement area, more excavation and digging work needed, complex module.

3. The underneath piled foundation

The underneath piled type wind tower foundation

The underneath piled type wind tower foundation construction

This type relies on the interraction force between the piles and the earth to fight against the overturning force.

The pros: large carrying capacity, minor settlement, small footprint. Suitable for coastal mud flat area, marsh area and soft earth area.

The cons: can be costly, the prestressed piles have an impact on the surrounding buildings, complicated technology process.

4. The uplift anchors

the uplift anchor type wind turbine tower foundation

The rock basement with anchor takes advantage of the great carrying capacity of the rock. The high strength prestressed anchors are fixed to the rock.

The pros: great carrying capacity, small footprint, concrete and steel saved. Suitable for mountain area.

The cons: anchors require better corrosion resistance coating, special rocks needed.

5. New types

new type wind turbine tower foundation

American type wind turbine tower foundation