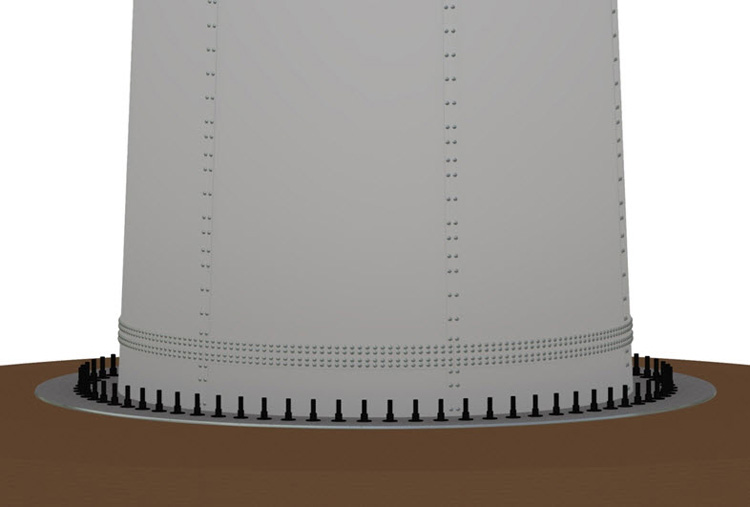

Wind turbine tower is the key supporting part for the wind turbine system, it bears the force of wind on the blades, like thrust, torque, bending moment, and vibration of the electrical machine. wind turbine tower is composed of 3 or 4 section of straight cylinder or conic cylinder which are connected together with the flanges at each ends though the high-strength bolts. So the quality of ovality, planeness, and angular distortion of flanges will directly affect the operation and working life of wind turbine.

The reasons of welding deformations of the flanges

When weld wind turbine tower flanges and the circular seam of cylinders, the groove type is internal groove. By the conventional welding sequence, firstly weld the inner side, then the outer side. Because of the high temperature in weld zone and flanges neck, under the unrestrained state flanges will be heated and expanded rapidly. The temperature of heat-affect zone of flange cooled slowly, so the shrinkage stress in the weld zone during cooling can not be counteracted. If the heat-affect zone is heated, wind tower flanges will be affected and produce an expansion stress, thus the inside of flange which is far away the weld zone will form valgus angular distortion. If the end of cylinder is not parallel and the flange places uneven, the flange will appears wave deformation easily in the welding process, and the flatness of flange will very poor after weld.

Processing measures for controlling deformation of flange

Method of rigid immobility. Connect two flanges which have the same diameter with fastening bolts at intervals of 4 to 5 bolt holes, and the gap between inside of the two should use sheet iron to stuff up.

Welding sequence of flange circular seam. When connect flange, the flange should slant at inside but plane at outside, and it could give the high-strength bolts homologous pretension force. So in the process of welding it can’t appear that inside is valgus. In addition, to avoid the phenomenon that inside is valgus, it must have a reasonable welding sequence. The inside should divide into two layers to weld, firstly weld the inner circular seam, at the same time, used carbon arc gouging for outside circular seam, after that weld twice weld joint directly. Then, weld the second layer at inside, when welding, it is required that this weld joint should be completed at once, and keep the heating evenly. In the process of welding should pay attention to control the technological parameter of welding, like the effect of welding current, welding voltage, welding speed on flange deformation, use small weld heat input as much as possible.

What should be attention in the process of welding

Appears cold crack after welding. Flange is forge piece, if the welding process parameters are not chosen properly, that will easy to cause the cold crack in the longitudinal direction of the weld seam near the weld joint and along the flange neck, and such the cold crack has the tendency to continue to expand along the place where has great rigidity. This delayed crack is lethal to the quality of the tower, and the flange crack can not be repaired, so must pay high attention to that.

Attention should be paid to the cracks in the heat affected zone of flange welding. prevent cold crack in welding heat-affect zone, minimize the amount of hydrogen diffused in the cold wind. Reduce welding stress and cooling speed, preheat the welding tongs and control the layer temperature. In addition, 48 hours after welding, the weld surface should be detected by MT, and the main inspection is that if there is the occurrence of cracks.