We all know that the wind turbine tower is the pole that support the upper wind turbine. It offers the height wind turbines need, therefore, for the outsiders, wind turbine tower seems like a complete steel tubular with such a huge size. But are wind turbine towers really only a one piece steel tubular? Of course not.

A complete steel wind turbine tower is dozens of meters high, with the fast development of wind turbine technology, the average wind turbine tower height is nearly 100 meters. Therefore, it is not possible to manufacture and transport such a huge steel tubular, so we have to separate the complete steel tower into several sections and weld flanges on the both end, and after we transport the wind tower sections on site, we will assemble the wind turbine tower sections together. Moreover, the electricity that generated by wind turbines need to be transport to the underground grid, so there are also many different types of components inside wind turbine towers.

Wind turbine tower parts is the general term of all types of wind turbine tower spare parts. In order to make a better knowledge about wind turbine tower parts, we can separate wind turbine tower parts into two parts: spare parts for wind turbine tower cylinder and foundation, and wind turbine tower internals. In the following article, we will mainly discuss the different types of wind turbine tower cylinder and foundation parts.

Spare Parts of Wind Turbine Tower Cylinder

Wind turbine tower is not just a welded steel cylinder. First of all, in order to connect wind turbine tower sections together, we need flanges to be welded on the both end of each wind turbine tower sections, and bolts to connect the neighboring two wind turbine tower sections. The materials of wind turbine tower flanges and bolts is similar with wind turbine tower materials, such as ASTM A709M Gr.50, and EN10025S355 steel. These types of steel are specially designed for wind turbine tower manufacturing.

Spare Parts of Wind Turbine Tower Foundation

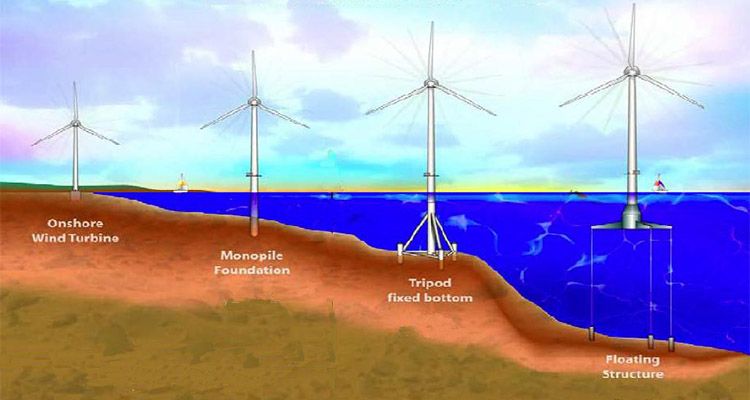

Except the flanges and bolts of wind turbine tower, to install wind turbine towers, we also need a strong foundation for wind turbine towers. The foundation of onshore wind turbine tower is different from offshore wind turbine tower foundation.

Onshore Wind Turbine Tower Foundation

No matter which types of onshore wind turbine tower foundation you choose, the foundation assembly connected wind tower foundation and tower sections is called anchor cage, which is consist of a wind turbine tower anchor plate, a wind turbine tower load distribution plate, and several anchoring bolts. Onshore wind turbine tower foundation parts are also made of quality steel, which is similar with wind turbine tower materials, or even better. Then with the help of steel bars and concrete, wind turbine tower foundation is strong enough to face the extreme environment.

Offshore Wind Turbine Tower Foundation

For offshore wind turbine tower foundation, there are three types of wind turbine tower foundations. First, monopile foundation is installed for the wind turbine towers located at the waters shallower than 30 meters. Second, tripod foundation is used for the wind turbine towers located at the waters between 30 meters and 60 meters deep. Jacket foundation is used for the wind turbine towers located at the waters deeper than 60 meters. As it is not so stable, wind turbine tower jacket foundation can only be installed at the water area with little waves.

Wind turbine tower monopile foundation and tripod foundation is made of steel tubular stands with corrosion resistant surface. And the jacket foundation of offshore wind turbine is consist of marine structural engineering foundation and anchoring and retention.

To install an offshore wind turbine tower system, there are also three different ways: jack-up installation, semi-submersible installation and float-over installation. The choose of three offshore wind turbine tower installation methods is fully depend on the depth of the water area, the capacity of the lifting machine and the load capacity of the barge.